Product overview

EcoVision CNC Software

We develop smart, time-saving solutions designed to simplify your daily workflows. Where standard tools reach their limits, our products step in—flexible, intuitive, and tailored to your real needs.

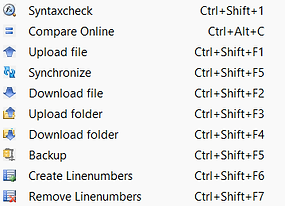

Use the Windows conext menu to manage you CNC files

Use the Explorer context menu for direct CNC access

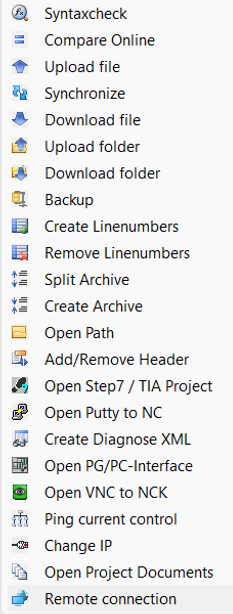

NCK-Interface

EcoVision CNC Software

The professional way to connect and work with your Sinumerik NCU. Copy, compare, back up, and synchronize CNC files easily using the Windows Explorer context menu.

Why use a USB stick when you can access it directly?

Use the NCU Synchronization Explorer to take your work with Siemens NC to the next level. Instead of using cumbersome file management methods, you can now easily achieve your goal with this new tool.

You won’t find these unique features in any other product.

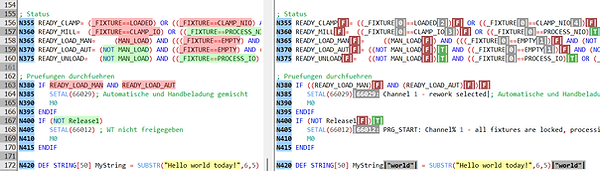

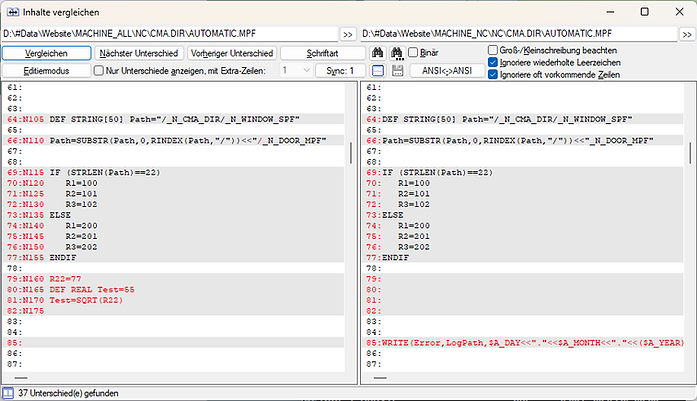

Unlike other programs that rely on the _N_ format, this tool correctly handles CNC filenames and offers powerful functions such as syntax checking and automatic CNC line numbering.

It also integrates seamlessly into the Windows context menu and provides a flexible command-line interface, making it easy to use within any other software environment.

Use functions such as syntax check to test your program before uploading it with NCK interface.

Create a diagnostic XML from a CNC file to monitor the variables on your TCU without having to enter each one individually.

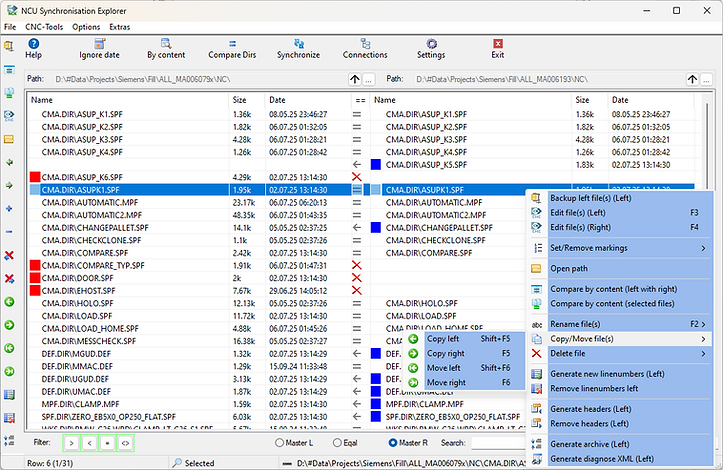

Connect directly to your Sinumerik NCU

Synchronize your CNC files directly

Sync, compare and edit your CNC files

Watch your CNC files online

Upload changes with 1 click

Instand help for each variable

Offline debugging of your CNC files line by line

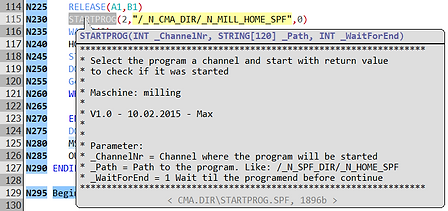

Subprogram descriptions

Online mode to look for faults

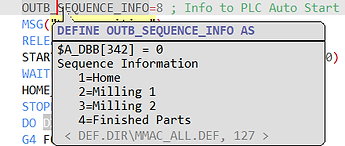

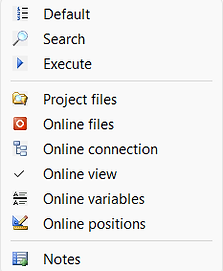

CNC-Studio

EcoVision CNC Software

Finally, there is a tool that is specially tailored to the needs of CNC programmer. Take advantage of CNC Studio and make working with Sinumerik 840D and Sinumerik One easy and convenient.

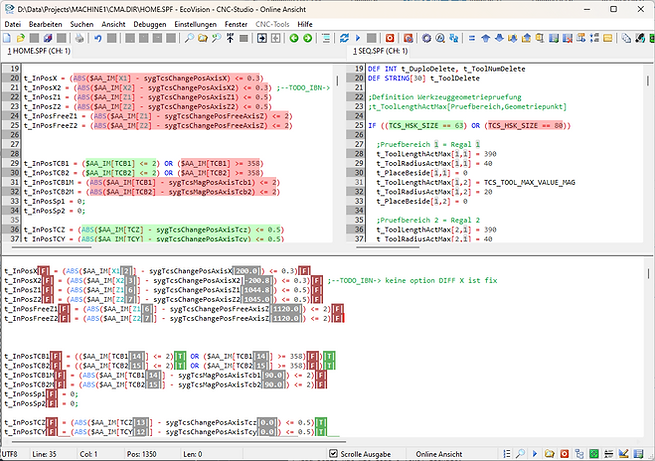

CNC Studio is a one-of-a-kind solution—the only editor that lets you monitor and edit CNC variables live.

It’s also the only tool with an offline debug mode, allowing you to test your program code line by line without a live machine connection.

Ideal for CNC programmer, maintenance personnel, and machine operators who want to work efficiently and professionally.

Learn how CNC programs work and how they are connected to each other. The CNC-Studio will help you understand what the program does and how it's subroutines and variables are linked to each other. Your get direct help for each CNC command.

Use the NCK interface integration to upload/download programs directly, compare them, or check the syntax.

Monitor CNC variables in online mode and quickly find out what is causing a particular problem and why a program is not working properly.

Compare your files with the online files befroe uploading them

Watch variables and conditions live

NCK-DataAnalyzer

Access machinedata, GUD's, drivedata, R-Par. , $NC-Vars, databases, ...

EcoVision CNC Software

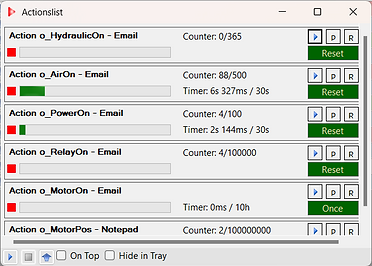

A tool with a wide variety of functions, from accessing machine data and event-driven actions to analyzing PLC and NCK signals.

Use event-controlled Actions to automate your tasks (send email, copy files, ...)

-

Analyze signals from multiple PLCs or NCUs.

-

Use powerful event-driven actions such as file management, process execution and message sending.

-

Export and import data blocks in STEP 7/TIA, with correct rewriting even after address shifts.

-

Access, record, and work with machine data, drive data, GUD, R-parameters, and most other NCK variables.

-

Use all read and calculated signals/variables to trigger actions or write them to other controls or databases.

-

Log signals into log files or database protocols.

-

Write data from controllers into a database – or the other way around.

-

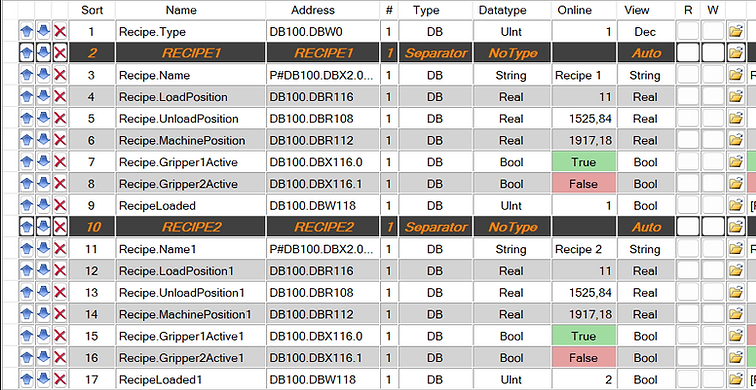

Recipe management – load recipes into machines.

-

Preventive maintenance – monitor hardware/signals and automatically send emails when hardware needs to be replaced.

-

Compare data and filter by differences.

-

Use a large function library to solve your problems.

-

Open CNC programs and monitor their variables.

Create recipes and trigger the loading with a control, database or file

Analyze and record you PLC and NCK signals with Charts

Interface Simulation - Test your machine and robot interfaces using the NCK- DataAnalyzer

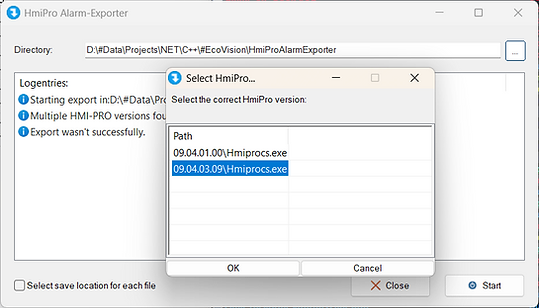

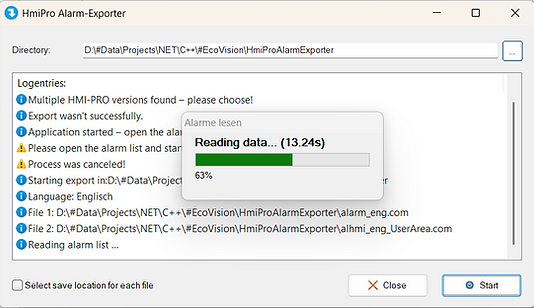

HmiPro-Alarm-Exporter

EcoVision CNC Software

Finally there is a way to export HmiPro Alarmtext quick and easy.

-

Export your HmiPro Alarm messages for every language used by the HmiPro program.

-

Use the exported files to compare them with other projects or translate them.

-

You can also use them for the Import, the files are in the correct format.