Features

Feature

Basic

Pro

Description

Automated Actions

Use event-controlled actions to automate your system (handle files, write logfiles, send emails, start programs, ...)

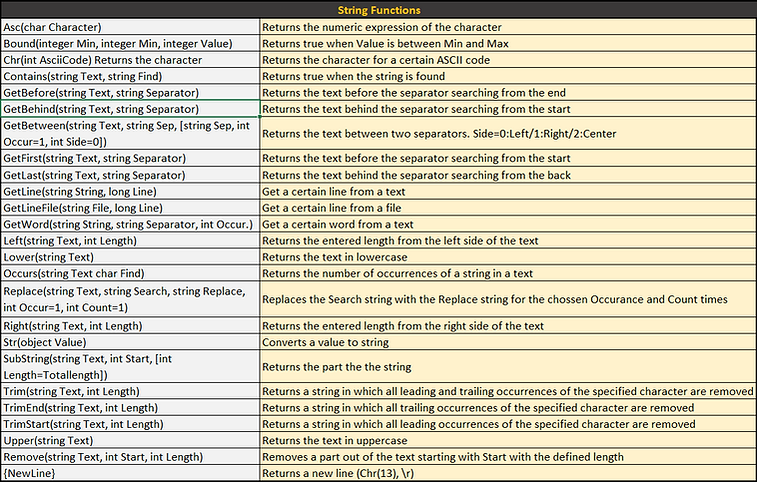

Advanced function library

Use many different functions for logic, calculation, string manipulation and system functions

Advanced import functions

Import different file formats TEA, DB, PRD, DEF, SPF, MPF, CSV, TXT

Analyzer Charts

Analyse you PLC/NCK/DB Data using charts

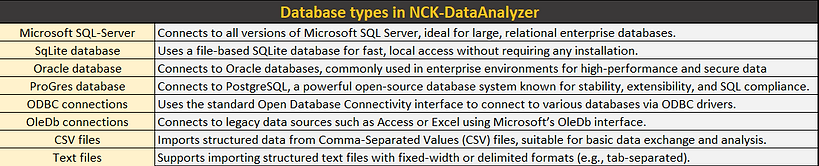

Database-Access

Access databases (SQL, SQ-Lite, ODBC, OLE, Oracle)

Drive-Access

Access drive data

Machinedata-Access

Access machinedata ($MA_POS_LIMIT_PLUS, $MA_POS_LIMIT_MINUS,...)

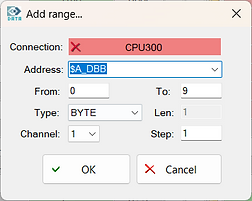

NCK-Access

Access NCK variables ($A_DBB, $R, GUD,...)

PLC-Access

Access multiple PLC's at the same time

Interface-Simulation

Simulate machine interfaces by reacting to incoming signals. Each signal can have a condition, can be delayed, and can use a multitude of available functions.

Save-Restore-Compare-DBs

Save, restore and compare DB's or other signals

Watch CNC-Programs

Open CNC-files and watch and edit all the variables used in the program

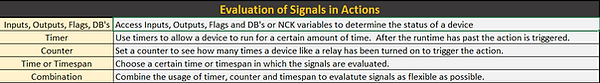

Automated Actions

Use actions to automate your system (handle files, write logfiles, send emails,...)

Work with PLC/NCK variables, inputs, registry, environment variables and database fields to determine the condition that starts the action. You can refine the query by using timers and counters that record, for example, how long a signal has been switched on or how often it has been switched on.

With the various functions available to create an action, you can automate just about any task. Here are a few examples:

-

Write predefined recipes to a controller

-

Record the runtime of devices for preventive maintenance

Send an Email when a device has to be changed. -

Copy files from one location to another when the controller sends a signal.

-

Start a program with parameters from the controller or database when a certain trigger occurs.

-

Shut down the computer when a command is received.

-

Automatically load CNC programs to the NCU when they are needed.

Advanced-Function-Library

Use a variety of functions for logic, calculation, string manipulation, date and system functions

You can use each function every time you read or write a signal from or the your PLC/NCU or database. This allows you to do complex calculations, manipulate strings or even access files to get the data you want to write into the control.

Examples:

Read the content of the file, convert the string to integer and divide the integer by 60: Output: the text in the file as int/60

ToInt(FileToString("C:\Text.txt"))/60

FlipFlop Signal Toggles every 500 ms: Output: true -> false -> true.

{MS}>500

Use the FlipFlop Signal to toggle the computer and user name: Output: {COMPUTERNAME} or {USERNAME}

IIF({MS}>500,{COMPUTERNAME},{USERNAME})

Output day of the week as string: Output: Mo, Tu, We, Th, Fr, Sa or Su

ICASE({NDOW}=1, "Mo", {NDOW}=2, "Tu", {NDOW}=3, "We", {NDOW}=4, "Th", {NDOW}=5,"Fr", {NDOW}=6, "Sa", {NDOW}=7, "Su","")

Add 1h to the current time: Output: 04.08.2025 10:28:44

{Datetime}+3600

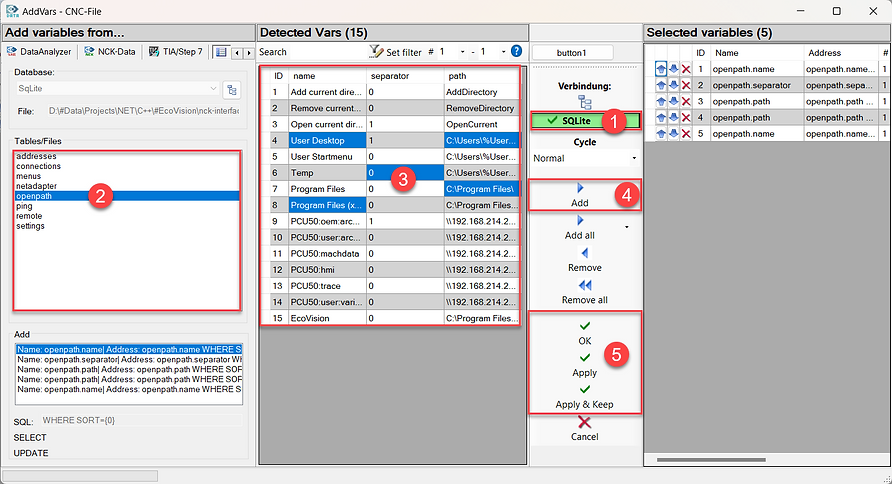

Analyzer Charts

Analyze your PLC and NCK signals and save the data for later use. All CPU300 - CPU1750 signals can be recorded, as well as signals from the Sinumerik NC. This includes machine data, GUD, R parameters, drive data, and almost all other NC variables.

Evaluate the signals with millisecond precision. You can set measurement lines and ranges and display detailed information about time-consuming processes.

You can easily import new variables from a variable table or add them directly using one of the many options (such as from Step 7, TIA, CNC programs, databases).

Interface-Simulation

Simulation an Interface between a machine and a robot or an automation and use the program to act like one of those devices.

Use Conditions to set and reset variables in 2 seperate lines or write the expression directly in the Value and let so it will always wirte true or false without a condition.

Watch the Interface Simulation at work

Save-Restore-Compare-DBs

Save and restore DB's from CPU300, CPU1500 or others. You can use the Refesh addreses function to make changes to your DB's or UDT's and restore the lost data with NCK-DataAnalyzer safely.

1. Add one or more DB's to the variables table and read the data.

2. Make changes to the UDT

3. Refresh the addresses in the DB and load it in the PLC

4. Refresh the addresses in the variables table and write the data in the PLC

Watch CNC-Programs

Open and watch CNC-Programs to see what values the variables, defines and results have.

You can use the “N in A” button for long combined variables and the program will show you all the variables in blue that are contained the expression so you can find them more easily. It will also show you a tooltip with the values split into individual variables.

Local variables are not read directly from the control, but are calculated using the variables contained in the expression that was used to assign the first value to the local variable.