NCK-DataAnalyzer

A tool with a wide variety of functions, from accessing machine data and event-driven actions to analyzing PLC and NCK signals.

-

Analyze Signals from multiple PLC's or NCU's.

-

Use powerful event-controlled actions like manage files, start processes and send messages.

-

Export and import of data blocks in STEP 7, even after address relocation

-

Access Machinedata, Drivedata, GUD, R-Parameter and most other NCK Variables.

-

Write Logfiles or Database logs.

-

Write data from controls to a database, or a databases to controls.

-

Recipe management, for loading recipes into machines.

-

Preventive maintenance, watch hardware and send emails if they have to be changed.

-

Compare data and filter for differences.

-

Use a big function library to solve your problems.

-

Open CNC-Programs and watch it's variables

Features

Feature

Basic

Pro

Description

Complete PLC and NCK access

Work with all variables types of from PLC and NCK.

Read or write data from the control to a database or other control. There is no limit on how many controls you can access at the same time.

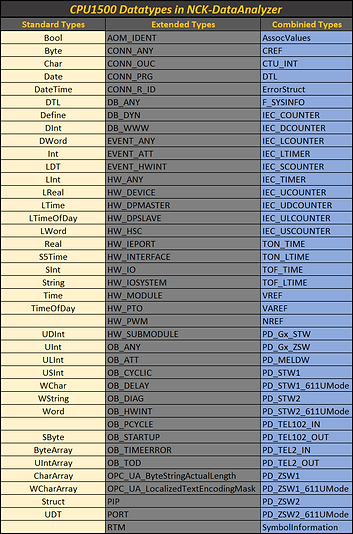

Work with all CPU1500 datatypes and use it for calculations or to write it into a different control, database or file.

You have plenty of options with which you can solve pretty much any task without having to create a costly and time-consuming high-level language project yourself.

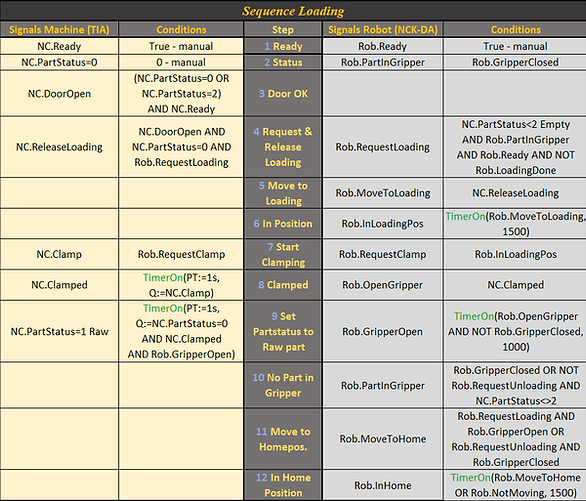

Interface Simulation

This allows you to communicate directly with the PLC/NCU and respond to signals as if you were the real interface partner. You can use timers and functions for maximum flexibility. Send the right signal at the right time and make sure the controller receives exactly the signal it is waiting for. It's easy to set up and add new signals later.

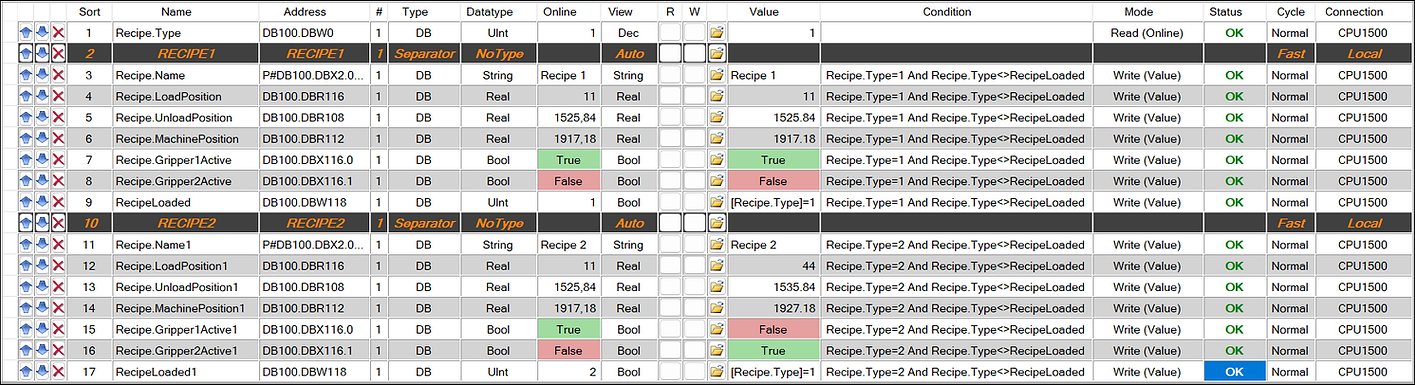

Recipe Managment

Create recipes and use flexiple triggers to load them into a PLC or NCK.

You can trigger the loading of recipes or other data by various means such as a DB variable, an NCK variable, a database field or a file.

Use conditions and the read/write mode to flexibly configure which data records are written.

Use automated actions to react flexibly to signals. You can use a variety of functions to easily process and reuse data from control systems.

For example, you can record certain signals from an NCU and write them to a database. Either cyclically or via a signal trigger.

You have plenty of options with which you can solve pretty much any task without having to create a costly and time-consuming high-level language project yourself.

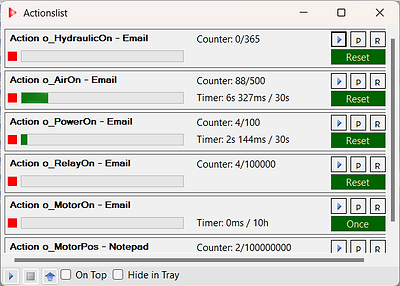

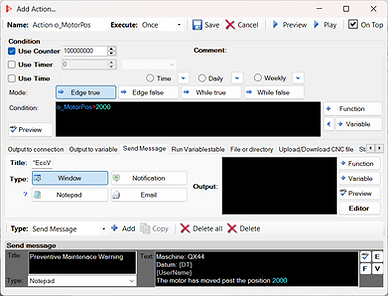

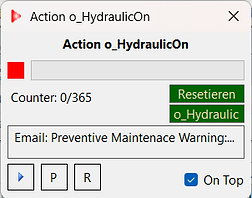

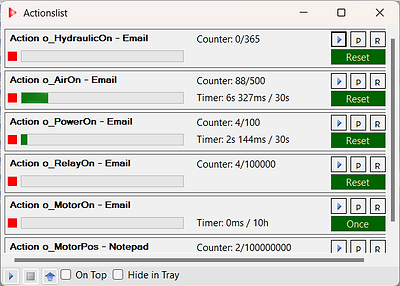

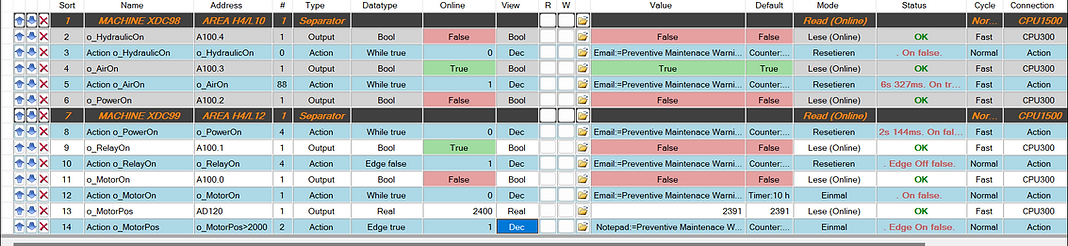

Preventive maintenance

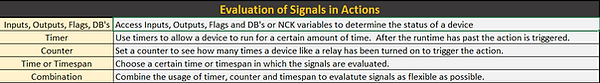

Use NCK-DataAnalyzer to watch your machine hardware. You can simply set up Actions to watch motors, relays, transformers or every other signal coming from a PLC/NCU or Database.

Simply select how many hours or times a specific signal should be detected before an action is triggered.

Actions are very flexible and allow you to perform almost any task. You can send e-mails to the maintenance manager, display messages directly, create log entries, write to databases or controllers, execute processes and much more...

This should make it possible to solve most tasks related to the evaluation of PLC/NCU signals to determine the usage of most machine components.

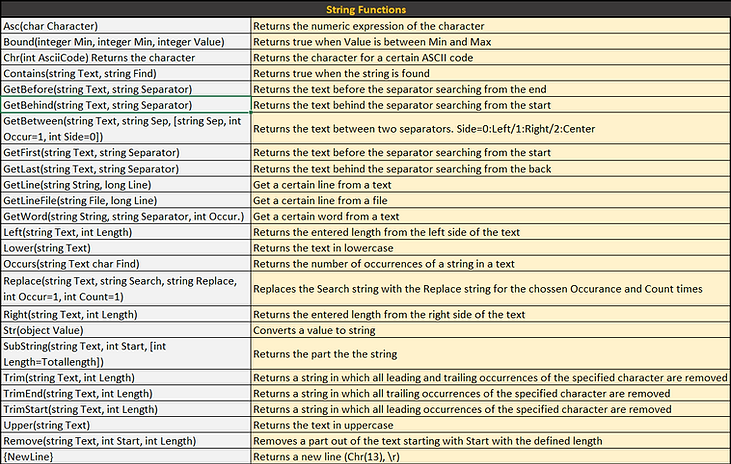

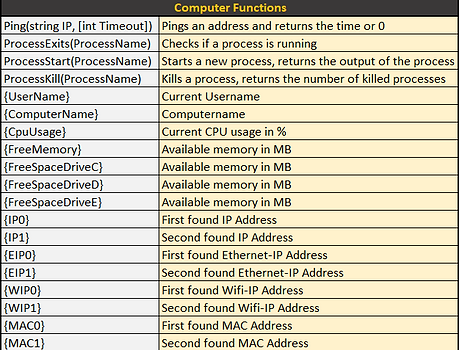

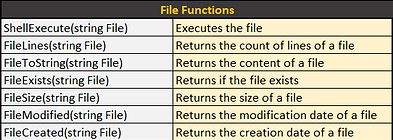

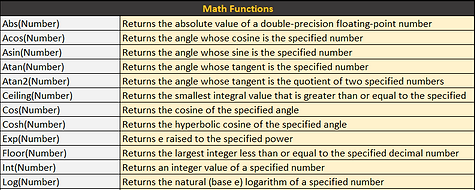

Advanced function library

Work with a variety of functions that help you realize any task you need to accomplish.

You can manipulate strings, access files, use math functions or calculate dates and times to send to a control or database.

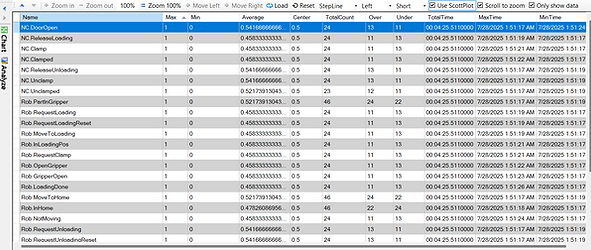

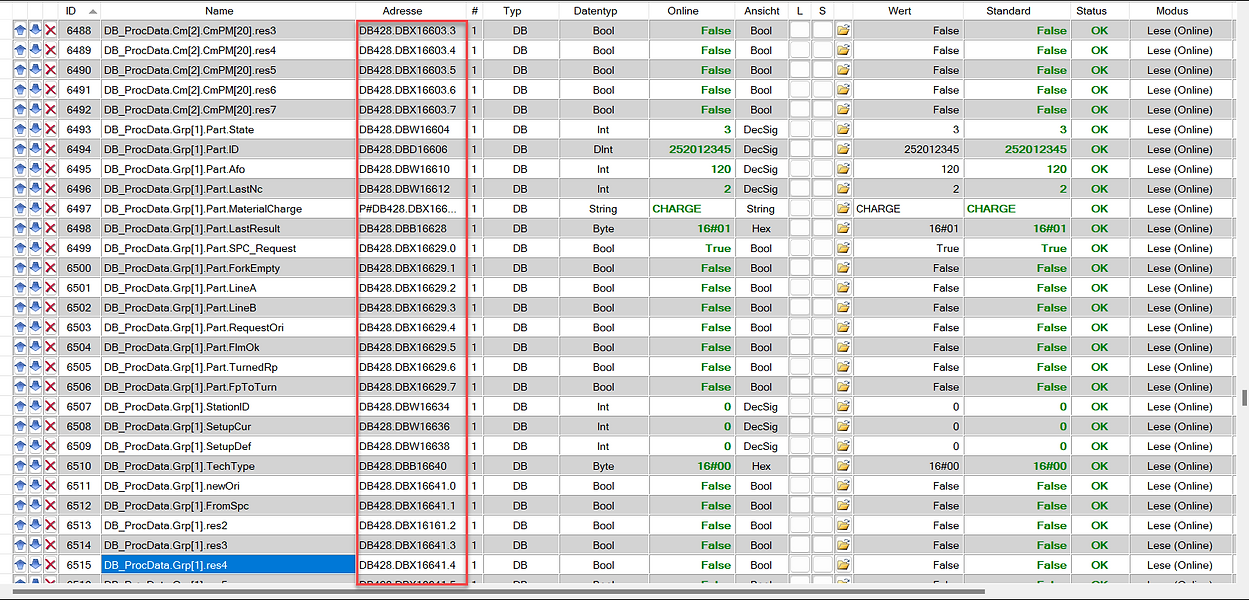

Analyze Signals

Record and analyze Signals from controllers or a database. You can use your predefined variable tables or simply add new signals from a lot of differernt sources like TIA, Step 7, machinedata, drivedata, databases and CNC-Programs.

Refresh addresses and restore the DB

Backup and Restore DB's

Add DB's with one click by using the Projecthistory context menu. Read it and backup it up and restore it in no time at all.

If you are working with Step 7 DB's and the adresses inside the DB have changed in the meantime, you can quickly refresh the addreses and load the data back into the DB. There is an Example of how to do this in the manual.

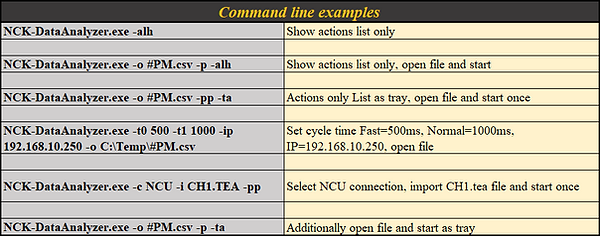

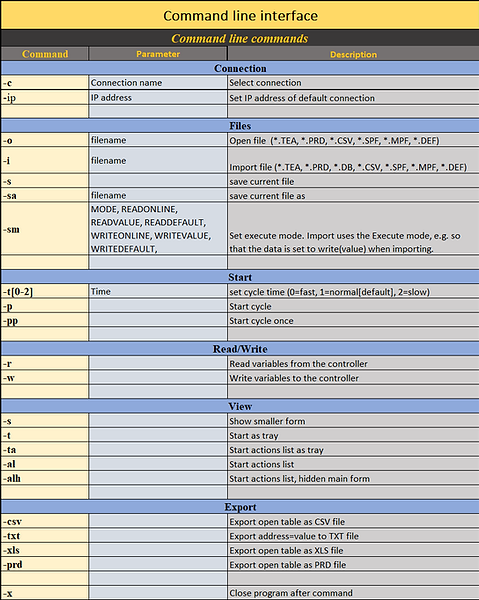

Commandline interface

Use the commandline interface to automate the NCK-DataAnalyzer.

You can use parameters to open a predefined variables table and load it into the control. This let's you access every device and control it by another program.

Start the NCK-DataAnayzer in Tray mode and start it at the same time to have it perform in the background and run tasks like load recipes, do preventive maintenance evaluation, ...