CNC-Studio

The most advanced editor for CNC programs

Finally, there is a tool that is specially tailored to the needs of CNC programmers. Take advantage of CNC Studio and make working with Sinumerik 840D and Sinumerik One easy and convenient.

CNC Studio is a unique studio for CNC programmers, maintenance personnel and machine operators who want to achieve their goals quickly and professionally.

Features

Feature

Basic

Pro

Description

Online mode

Use the CNC-Studio to directly connect to an NCU and monitor CNC programs online to quickly analyze the program and locate problems. With the benefit of seeing the current values directly in the code, instead of having to add each variable to the online list on the NCK.

This way is much more efficent and comfortable.

The Online mode is a powerful tool that let's you directly access the NCU and watch and manipulate variables. Be aware that this can cause problems and should only be done by advanced users. We recomment createing an archive and using the save Offline mode environment at the beginning.

Even in Online mode you can always decide if you want to write values or execute lines directly to the NCU memory or if you only want to write them into the local memory. Use Set value and Execute line for local access only and Set value (to control) and Execute line (to control) for direct NCU access.

Watch you CNC-Program online

Check that your calculations are correct.

On the left-hand side you will see the actual program with conditions highlighted in red and green so that you can easily see what the program does.

On the right-hand side you will see the online output with the current values of all the variables.

Direct access to relavant data

The program automatically evaluates dynamic index parameters like R[200+DBI_TypSide1W1] to R[202] and shows you the relevat information. You can change values by using the context menu or assign them with the Execute line command.

Watch you CNC-Program online

Test functions like Write - to see the output in the files

Test functions during the development with F11 like the Write file function that will actually write the data in correct NCK file on your windows drive.

Evaluate your text outputs

The output window will show you the correct text for multi language variables like $86840 and show the endresult of joined together strings, so you don't have to load the program and start the NCK to test your program.

Recognize conditions at first glance

By highlighting false and true conditions in color, you can easily see why a variable is not set.

Watch, test and manipulate your CNC-Programs on you laptop

Execute Lines

Directly execute lines and watch the values change in the output window right away.

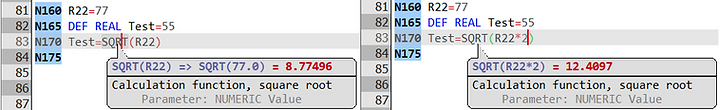

Evaluate functions

You can use the offline mode to test your code and look at the function results while you writing the program.

Change Online/Offline values

Offline mode

for developing new programs

The Offline Mode is an innovative and efficient way to test your programs while you write them — without the need for a physical NCU or expensive simulation software.

It is a powerful tool with which you can work more professionally, more flexibly and much faster than if you only use a simple text editor.

Offline mode

for save and efficent troubleshouting

The offline mode can also give you a save environment to analyze and troubleshoot active machine programs.

Instead of risking working on the real machine, you can simply use the offline mode to look into a problem.

Only 3 easy steps will allow you to work offline on the current CNC program while having all the active data and variables with no risk to the actual machine.

1 . Create an archive on the machine you want to work on. You can even do this while the program is running to get the most current and acurat data.

2. Extract the CNC program from you ARC or DSF file by using the NCK Interface split archiv function.

3. Open the program in CNC-Studio and activate the Offline mode.

By using the Sinumerik archive which contains all current machine values at the time the archive was created — you can view the program as if it would run on the machine, with the correct values.

Advanced tooltips

Every time you open a CNC-Program, the CNC-Studio automatically adds all variables, functions, comments and CNC-Commands into a tooltip database.

This makes working with CNC-Programs much easier and faster. You can learn how a programs works in no time.

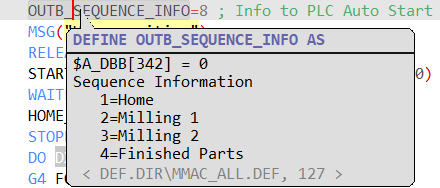

You can look up Defines and other parameter, to help you understand the program quicker.

Subprograms

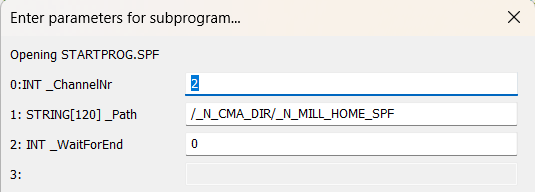

You get a tooltip for each subprogram header so you can see details about it. Open if with Paramters by using go to definition (F12).

Start Subprograms directly with the correct parameters and test the if the code is working correctly.

You get a tooltip for each subprogram header so you can see details about it before you open it with F12 Goto Definition. This will allow you to change the parameters before you run the subprogram.

Alarmtext display and access

View and access MSG Alarmtexts with tooltips and by using the go to definition command in the context or toolbar.

View and access SETAL Alarmtexts with tooltips and by using the go to definition command in the context or toolbar.

Change the alarmtexts quickly and without have to search the correct file first.

Output modes

Online/Project files

Use different output types to help you with additional information.

A list of all local files and CNC files on the NCU.

To Up-/Download and compare CNC-Files, you need the NCK-Interface.

Online variables

Add, watch and change variables from you program, for quick access.

Online view

Online positions

View the open CNC-Program online and watch and change the variables.

Shows you all axis and there current positions that are used in your project.

The axis configuration is extracted from the archive or directly from the NCU's MD

CNC-Help

Get context help with F1 for all CNC commands, functions and parameters.

You can save a lot of time by avoiding having to search the internet or manuals every time you want some quick information about a G-Command or one of the other more then 500 commands.